The ‘Secret’ to Top-Quality Horse Hay

Not many farmers can satisfy the finicky hay standards of Lexington, Kentucky, horse farms. Rick Hord not only can, but has done it for 10 years from his family’s Tollesboro, Kentucky farm.

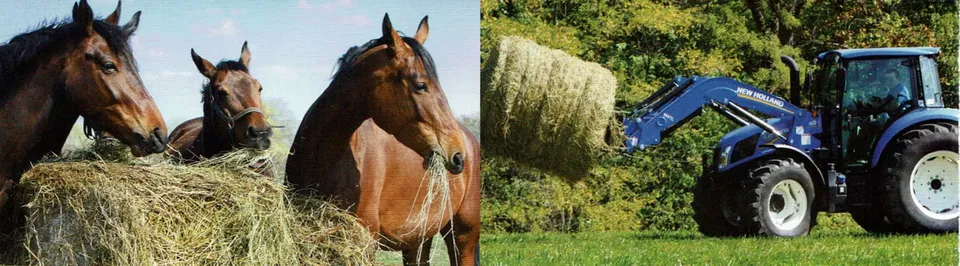

The family, which includes Rick, his wife Teresa, and son Brett, make hay – lots of it – for the Lexington horse market and their own cow herd. “We’ll square bale anywhere from 5,000 to 6,000 bales a year, and roll anywhere from 800 to 900 large round bales,” says Rick Hord. Hard also runs a registered Charolais herd, selling around 70 registered bulls and heifers annually.

Top Quality Demanded

What’s the secret to making hay for some of the most expensive horses in the world? “Horse farms are finicky about their hay,” Hord says. “They look for qualities way beyond what most cattle or dairy farms would see as good quality. For example, when they break open a bale, if the color isn’t almost as green as growing grass, they won’t buy it. They also look closely at the amount of leaves on stems. There has to be a lot of leaves.”

“I don’t know the secret to making top quality hay,” Hord adds, “but I’ll tell you how I do it. It’s a three-day process for me. The first day I cut with my Discbine® disc mower-conditioner. That afternoon, or the next morning, I ted it. Then on the third day, around 10 in the morning when there is still a little dew on the hay, I rake it. Then as soon as I get it raked – if it’s a good sunny day – I bale it. The hay still holds a little moisture, and will be green in color.”

His square baler is close to 40 years old, but still does a good job, Hord says. He uses a New Holland BR770 round baler to bale his cattle hay and has a new 24-speed New Holland T4.120 tractor to power his equipment.

Some farmers rake hay one day, then turn it again the next day before baling, Hord notes. “When you do that, it can dafe the hay to a bleach, tan-looking color – not the green color horse hay buyers demand,” he cautions. Hord tests hay for protein. “Than tan, brownish color doesn’t hurt hay’s protein content,” he says, “but horse farms want green color hay.” Some of his hay tests as high as 24 percent protein.

“Horse farms are also particular about hay maturity,” he adds. “A key to making good alfalfa hay for the horse market is to cut it every 30 days.” Hord seeds most of his hay ground to a mix of alfalfa, timothy and orchard grass, but also has some straight-grass fields. “Some horse farms prefer alfalfa-grass hay and some just grass hay. About 75% of my hay acres are seeded in alfalfa, timothy and orchard grass,” he says. “Over time the mix changes as timothy grows better in some fields, and orchard grass in others. Some fields maintain a quality stand up to nine years. When a field needs re-seeding, Hord plants it to corn or soybeans for two years. “The purpose of planting corn or soybeans is to get rid of the weeks and fescue. Then after two years, I sow alfalfa, timothy and orchard grass mix and always end up with a good field of hay.” In 2017, he did this with 33 acres of hay – planting it to corn. It was the only corn on his farm.

Ag Student Connection

Hord got into the Lexington horse hay market through several former students. Hord taught vocational agriculture for 28 years, retiring from teaching in 2007. He started teaching while farming with his father, Kenneth, and after his father retired, he ran the family farm on his own.

“A number of the students I taught in high school went on to work on Lexington area horse farms,” he says. “Several still work there and have hay hauling businesses. I sell to them and they re-sell the hay to the horse farms.”

During his last year of teaching, Hord’s FFA students won both the Kentucky and national FFA welding contests and the contest and the Mid-South Fair in Memphis, Tennessee.

Purebred Charolais Herd

Hord’s pride and joy is his 70-cow Charolais herd. Half the cows are calved in spring and half in the fall. Bulls are sold from 12 to 18 months of age, heifers at around 15 to 16 months. Bulls and heifers are sold both privately and at Hord’s annual sale, held each spring at the Bluegrass Maysville Stockyards in Maysville, Kentucky.

Why Charolais? The Hord family ran a Grade A dairy until 1974, the year Rick went off to study at Morehead State university. in the switch from a dairy to a beef cow herd, the Hords found themselves with half Hereford-half Holstein heifers – the result of having bred some of their Holstein cows to a Hereford bull.

“We bought a Charolais bull to increase the muscling and performance of the herd,” Hord days, “And then we also traded some of our dairy cows for registered Charolais sows. That’s how we got into Charolais. Because of their performance – the Charolais outgrew everything – we kept Charolais replacement heifers, used Charolais bulls and within four to five years we were all purebred.”

Hord has worked to steadily improve his herd, primarily by buying top bulls. “I try to use the modern bloodlines, and buy mostly embryo transfer bulls.” He sells to other breeders and commercial farms, with around 90 percent of his bulls and heifers going to commercial farms.

Who: Rick Hord

Where: Tollesboro, KY

New Holland Equipment: Discbine® H7220 Disc Mower-Conditioner, ProTed™ 3417 Rotary Tedder, Rolabar® 256 Rake, BR770 Round Baler, 311 Square Baler, T4.120 Tractor

Dealer: Rose Farm Supply – Flemingsburg, KY

This story is an excerpt of a featured story in the New Holland News Magazine – Spring 2018